Welcome to Eg Electronics

Professional services in

industrial electronics

Our dedication, empathy with the client and know-how are our cover letter.

>> EG Electronics, our Company

Young, professional and committed to its customers company

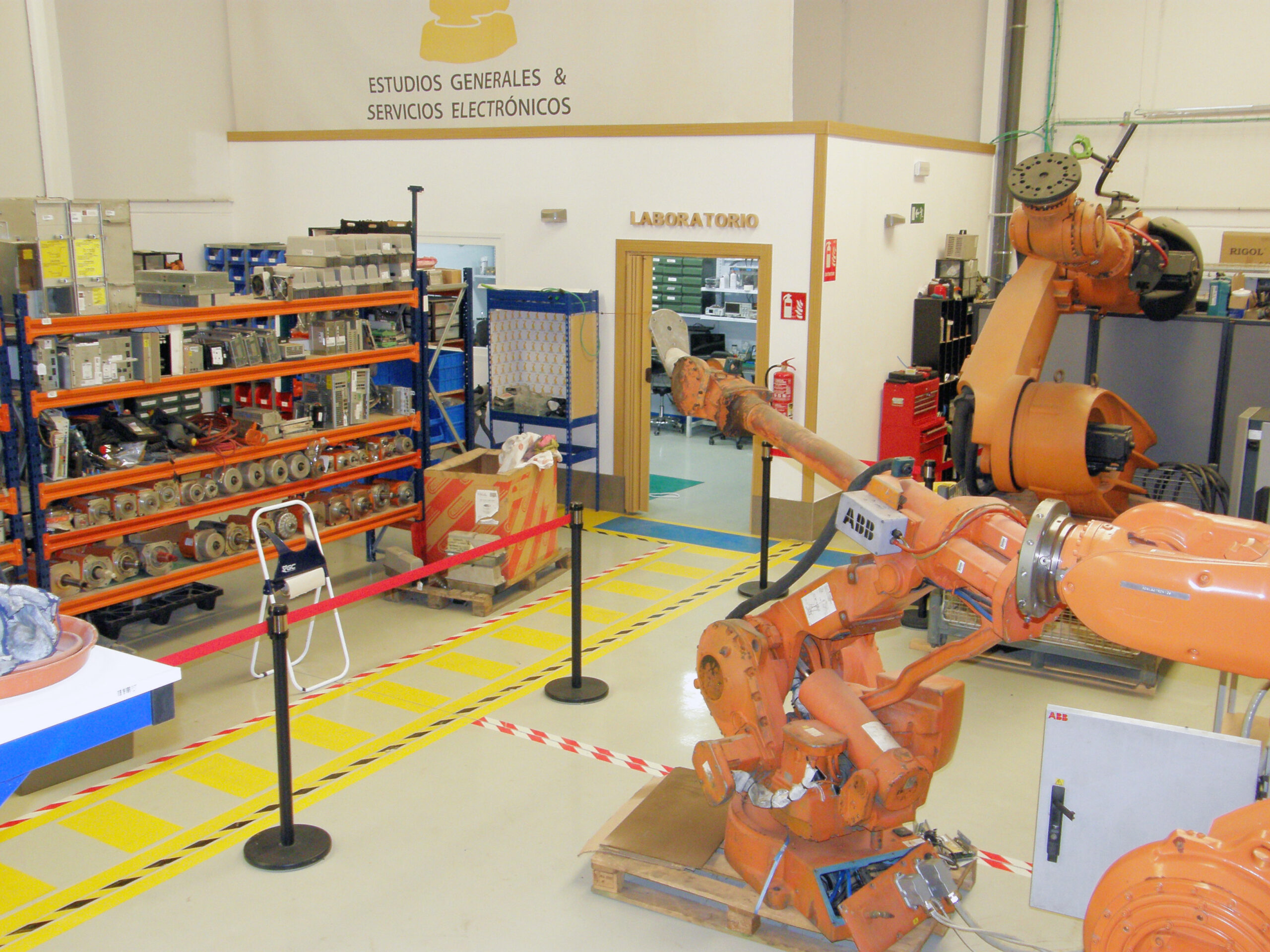

At EG Electronics we are dedicated to the repair of industrial electronics and the sale of power electronic components.

Our company is specialized in electronic repairs in ABB, KUKA, FANUC, SIEMENS, YASKAWA, being an alternative in repair, giving our clients a guarantee on all our repairs and exchange products.

We have collaborators/suppliers in most of the modules in addition to our own stock. Likewise, we have a network of collaborators in after-sales service, with the aim of supporting the needs of our customers.

Estudios Generales y Servicios Electrónicas S.L, we are trained to repair servomotors, speed variators, … for which we have equipment and test benches that allow us to carry out the repair and verification with full guarantee. We also have the sale of batteries for the industrial sector, robotics, plc, etc…

Our services

Our commitment to customers

Repair of automata

HMI Repair

Servomotors

Industrial electronics

Industrial robotics

Programming

>> FAQ

- 1 year warranty on repairs and exchanges.

If the repair of the servomotor is not possible or its cost is greater than the value of the product, EG Electronics is in a position to offer exchange or sale equipment thanks to our permanent stock, minimizing the downtime of the damaged equipment.

At EG Electronics we have the most precise technology on the market, allowing us to make the encoder perfectly calibrated at its mechanical 0.

Any component has its maximum level of hours of use rated by the manufacturer. Servo motors are no exception.

We recommend our customers to carry out maintenance on their servomotors in anticipation of future failures or breakage in their equipment.

In the long run, the costs of an unplanned shutdown in the event of failure or breakage are always higher than those of a technical shutdown for maintenance/replacement.

Oil leaks within the winding or brake wear causing loss of precision in the robotic arm.

Both can be avoided by performing annual maintenance.

- Todo

- Oficinas

- Laboratorio

- Almacén

- Área de pruebas

- Taller Servos

Servicios de mantenimiento, reparación, reacondicionamiento, venta e intercambio de componentes electrónicos para robótica industrial.

Servicios de mantenimiento, reparación, reacondicionamiento, venta e intercambio de componentes electrónicos para robótica industrial.